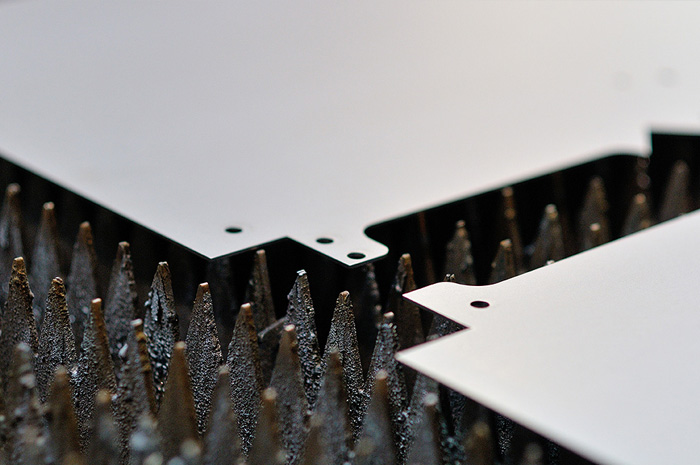

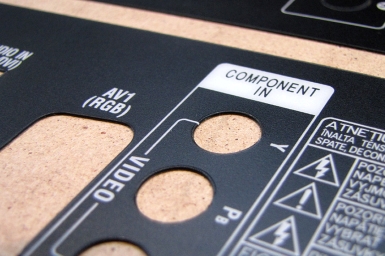

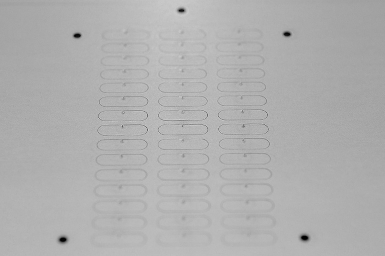

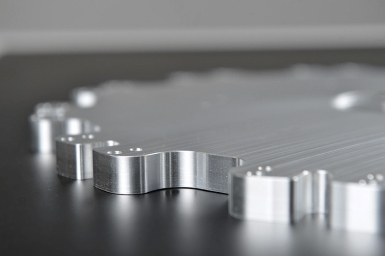

Metal laser cutting

Laser cutting is a modern way of processing material. The laser emits a very powerful light beam which is able to heat up the metal to a very high temperature, allowing it to be cut or welded. Laser cutting is very precise, as it allows a high degree of accuracy to be achieved, even with very complex shapes. This is particularly important in the manufacture of precision products such as automotive parts or electronic components.

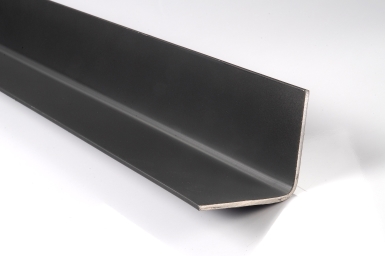

Sheet metal bending

Bending is a process in which sheet metal is shaped using force, usually with the help of specialised machinery. The machines most commonly used in this process include press brakes with different forces and length of the operating edge. These machines are characterised by high versatility of material forming and the repeatability of the production process.

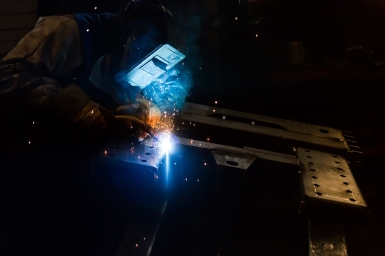

Welding

Welding metallic materials is the process of joining two or more components using various welding techniques: electric, laser, plasma or gas welding. Welding is widely used in Welding is widely used in industry as it provides long-lasting, robust bonds between metal components. between metal parts. It can be applied to various types of metals, including steel, aluminium, copper or nickel.

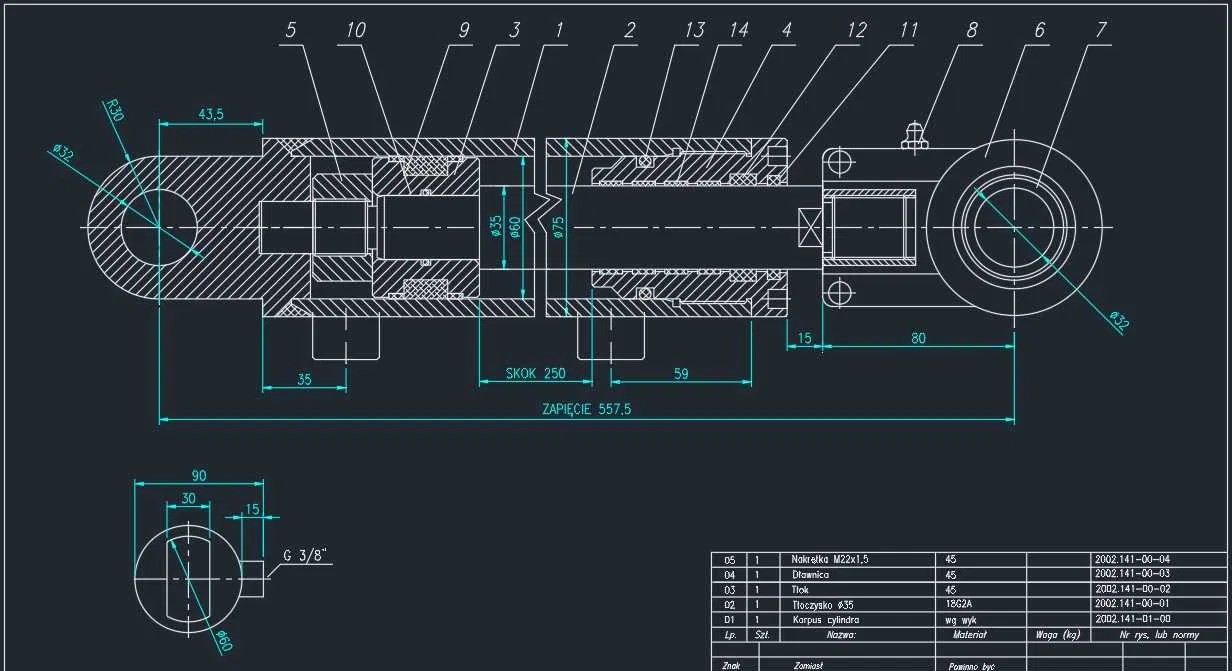

Design

Product design is the process of creating the design and dimensions of the product to be created by laser cutting. A suitable type of sheet metal or other material. The thickness of the material is of great importance, as it can affect the accuracy and speed of cutting as well as the dimensions and shape of the product, taking into account its intended use and specific requirements. It is also important to bear in mind the tolerance margin and the possibilities of technological possibilities of laser processing.

Professional Cutting

Professional Cutting